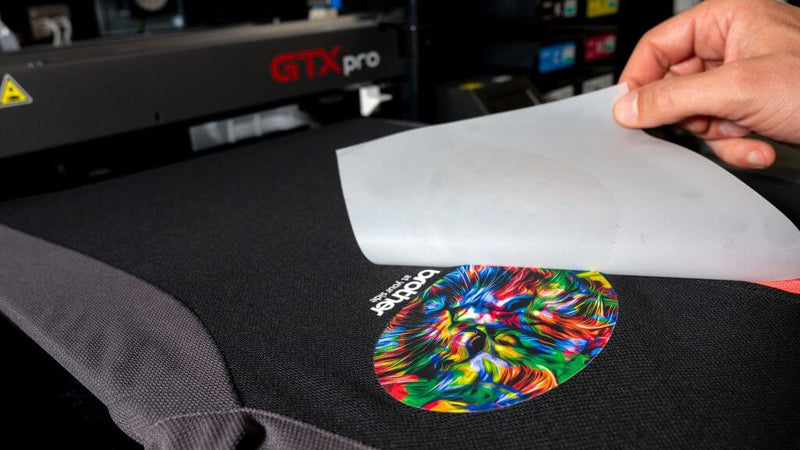

DTG PRINTING

Direct-to-garment (DTG) printing is a cutting-edge method that transforms your garment into a canvas for high-quality prints. Using advanced inkjet technology, this process allows us to print vibrant and detailed designs directly onto the fabric. The result is a soft and flexible print that seamlessly integrates with the material. DTG printing is ideal for creating custom t-shirts and various garments, making it a top choice for small businesses and individuals seeking efficient, high-quality, and short-run printing solutions.

DTF PRINTING

DTF (Direct to Film) transfer is a cutting-edge method for clothing customisation. It offers both single-color and multi-color printing, allowing for dynamic designs. What sets DTF apart is its ability to print over seams and on curved cap edges, providing a unique aesthetic. This technique is not limited to external surfaces; it's also perfect for printing branded tags, adding a professional touch to your garments. Unlock your world of DTF printing today!

EMBROIDERY

Embroidery is a classic and timeless method of adding a touch of sophistication to your garments. This technique involves stitching thread into fabric, creating intricate designs and patterns. Whether you're looking for a simple logo or intricate artwork, embroidery offers a versatile solution. It provides a durable and professional finish, making it a popular choice for adding a personalised and stylish touch to clothing.

Heat Transfer Print Methods

3D Puff Print

Ultra Reflective

UV Colour Changing

4D Silicone Print

Glow in the Dark

Vinyl Print

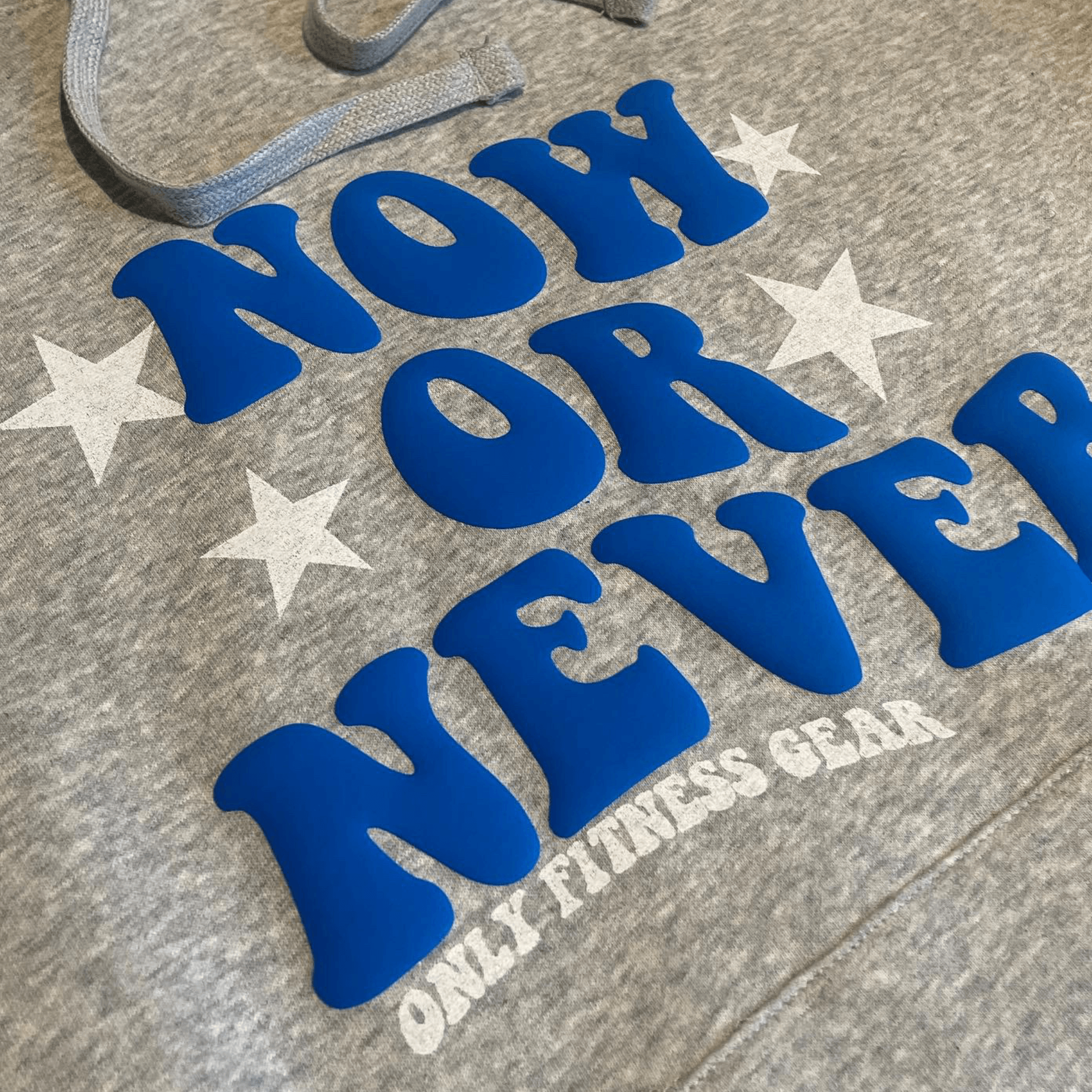

What is 3D Puff Printing?

Heat Transfer Vinyl (HTV) 3D Puff Printing adds an exciting 3D effect to your designs.

First, your design is printed on a special HTV material. Then, with heat and pressure, the design is transferred to the garment or chosen item. This technique gives your design a raised, three-dimensional look. By including a foam layer in the HTV material, the final result is a visually appealing and touchable design.

Examples of 3D Puff Printing

Puff Printing Requirements

Puff Printing prices are calculated by the complexity and size of your design. Smaller and less complex designs are cheaper and larger more intricate designs will cost more as they use up more material.

Puff print only works with a single colour, if your design contains multiple colours, please consider mixing print methods, such as Puff Printing overlapping DTG Printing.

What is Ultra Reflective Printing?

Ultra-Reflective Vinyl Printing takes visibility to a whole new level by incorporating reflective elements into your designs.

This advanced printing method utilises a special vinyl material that, when hit by light, reflects it back with enhanced brilliance. Going beyond the standard grey or silver, our Ultra-Reflective Printing offers a diverse array of colors to infuse your designs with both style and safety. Perfect for creating high-visibility apparel and accessories, this technique ensures that your designs pop, day or night. Elevate your creations with Ultra-Reflective Vinyl Printing, where safety meets style in a spectrum of vibrant hues

Examples of Ultra Reflective Printing

Ultra Reflective Printing Requirements

Ultra-Reflective Vinyl is available in a large variety of set colours. Each colour goes from the non reflective style to reflective when exposed to sharp lighting.

In order to meet the requirements the design must be a vectorised outline. It works best with block shapes, lettering and logos. Reflective printing will not work with designs that need to be more than one colour.

What is UV Activated Printing?

Experience your designs in a new light with UV-Reactive Vinyl Printing.

This cutting-edge printing method unleashes vibrant colours that come to life under ultraviolet (UV) light. Perfect for creating eye-catching, dynamic designs for events, festivals, or unique fashion statements. The special vinyl material reacts to UV light, creating a dazzling effect that adds an element of surprise to your creations. Elevate your designs with UV-Reactive Vinyl Printing, where every piece becomes a canvas for stunning, UV-activated artwork.

Examples of UV Reactive Printing

UV Colour Changing Printing Requirements

UV Activated printing changes from white to a set colour when exposed to UV light or sunlight.

In order for your design to fit the requirements, it must be a vector design. Designs which are larger and more complex will be more expensive.

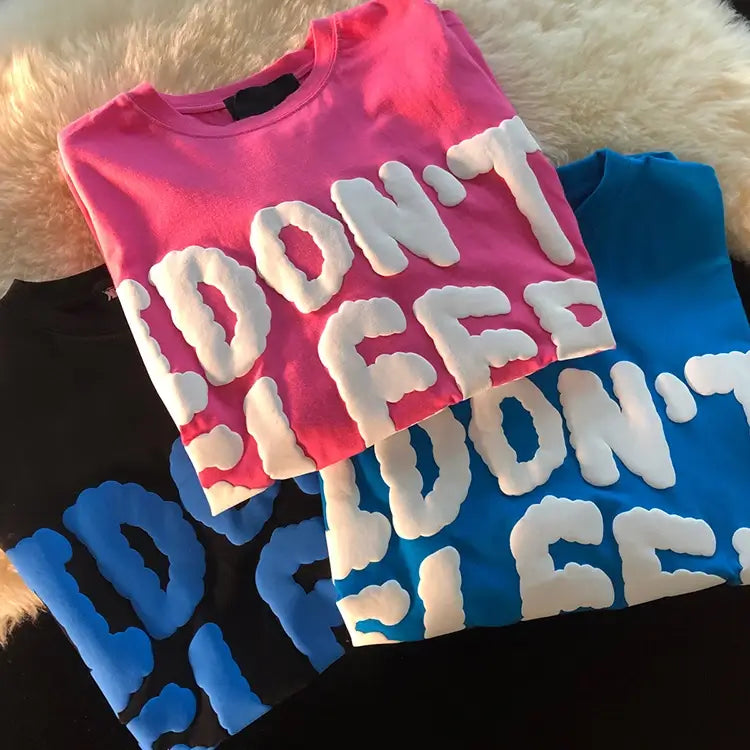

What is 4D Silicone Printing?

4D Silicone HTV Printing is an innovative and engaging method that combines heat transfer vinyl (HTV) with a silicone layer.

This dynamic technique not only imparts a vibrant and durable print on fabrics but also introduces a tactile dimension to the design. The silicone layer elevates the print, creating a unique three-dimensional effect that captivates both the eyes and hands. This process is particularly effective for producing detailed logos, branded labels, and intricate designs on a wide range of fabrics. The result is a visually striking and touchable print that adds depth and character to garments and other printed items.

Examples of Silicone Printing

Silicone Printing Requirements

4D High Build Silicone printing is available in a set number of colours and can be applied to a wide variety of printing locations.

For a design to be silicone printed, it must be a vectorised logo and not be too compplex/intricate. We do not recommend silicone printing designs which have a diameter smaller than 1cm.

What is Glow in the Dark Printing?

Glow-in-the-Dark Vinyl Printing adds a luminous twist to your designs, making them stand out even in the dark.

This captivating technique involves using a special vinyl material that absorbs light during the day and emits a subtle glow when darkness falls. Ideal for creating eye-catching apparel and accessories, this printing method allows your designs to shine with a unique radiance. Whether you're looking to add a playful touch to garments or enhance safety visibility, Glow-in-the-Dark Vinyl Printing offers a creative and functional solution. Elevate your designs by incorporating this illuminating feature that adds an extra layer of charm to your printed items.

Examples of Glow in The Dark Printing

Glow in the Dark Printing Requirements

Glow-in-the-Dark Vinyl Printing starts as a white material and is charged up by being exposed to natural lighting.

Similar to all vinyl, designs must not be too large or overly intricate in order to receive a consisent and high quality result.

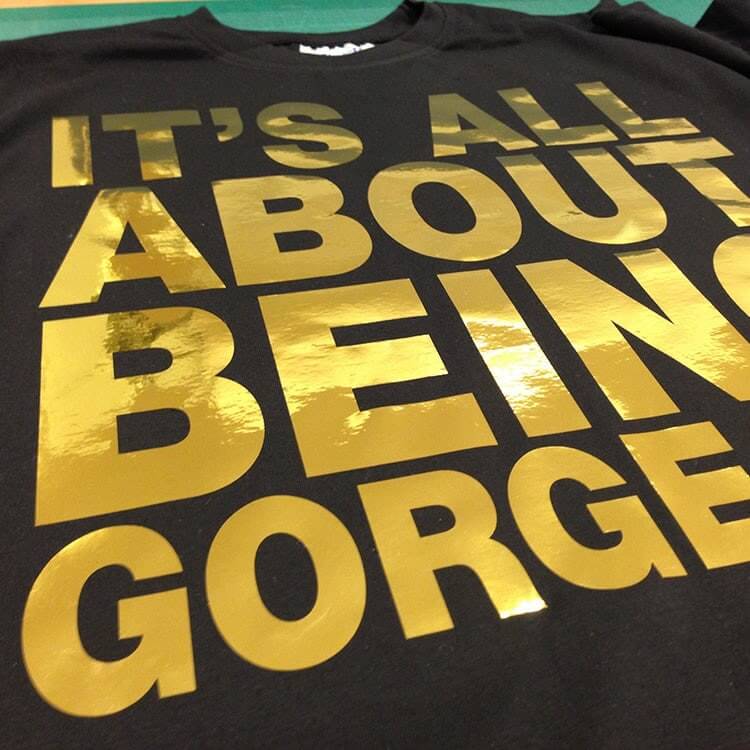

What is Vinyl Printing?

Vinyl Printing is a versatile method where a design is cut onto a sheet of vinyl and then heat-pressed onto the fabric.

This process ensures a durable and long-lasting print. Vinyl comes in various colours, making it easy to create vibrant and intricate designs. It's a popular choice for custom apparel, allowing for precision in design placement and vivid color outcomes.

Examples of Vinyl Printing

Vinly Printing Requirements

Vinyl Printing allows for combining colours and is perfect if you need block colouring or need to print onto an unusual material.

Designs must be vectorised and combining different vinyls such as flock, glitter or holographic is possible. Keeping your design as simple as possible will allow you to access the cheapest cost.

Garment Finishing

SCREEN PRINTED NECK TAGS

GARMENT POLYBAGGING

Want to increase your brand awareness and add a more sophisticated finish to your products! We offer screen printed neck labels!

Minimum Order 20 Units

Want retail ready garments? Go for our bagging service! All items come steamed & bagged with size label stickers and washing instruction cards!

Minimum Order 20 Units